PURPOSE:

To calculate the propagated error in measuring the density of metal cylinders.

INTRODUCTION:

We are simply measuring the mass, height, and diameter of two metal cylinders in order to determine the propagated uncertainty inherent to their measurements. To do this, we will utilize the sum-of-squares method for the total differential of the density function: mass/volume. Where volume = ∏r2h. This method will allow us to see how much uncertainty there is in our calculation of the density of a given metal cylinder.

PROCEDURE:

To do this lab, you will need the following materials: calipers, scale, and two metal cylinders.

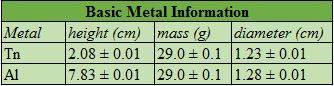

1) Record the B.M.I. (Basic Metal Information) of your two metal cylinders using the calipers and the scale. These measurements include height, mass, and diameter. Make sure to include the uncertainty in each measurement as well. It will come in handy for our final calculations. These are the measurements we recorded:

2) Derive an expression for the density of a cylinder in terms of the three variables we measured. This will allow us to find the total differential in terms of h, m, and D. Note: the terms dm, dh, and dD represent the uncertainty in mass, height, and diameter, respectively. Finally, use the sum-of-squares method to derive an equation for the propagated uncertainty in the density of a given metal cylinder. Below is the derivation of our equation:

3) Calculate the propagated error for each of your density measurements. It is simply plug-and-chug from here on out. Here are our propagated error calculations for the tin and aluminum cylinders:

CONCLUSION:

According to our calculations, it appears that our measurements for the density of the aluminum cylinder were much more accurate than that of the tin cylinder.This difference in uncertainty was most likely the result of human error. For example, an inaccurate reading of the calipers could have resulted in a higher uncertainty in our calculations. Another possible source of error is faulty equipment. For instance, the scale we used would often oscillate between 29.0 and 29.1 g whenever we measured the mass of our cylinders. This could be an indication that our equipment was not as precise as we needed it to be.

GROUP MEMBERS: Matthew I., Xavier L., Billy J.

No comments:

Post a Comment